After about 2.5 years, the sink macerator in our 2018 Revel stopped functioning effectively, resulting in a slow drain that sometimes required us to use the palms of our hands as a plunger. After seeing Guido Lyons' post in the Facebook group about replacing the impeller, I finally ordered the parts and did the job. I have to say that this is one of my least favorite maintenance items in the Revel, and needs to be made simpler. I took the lazy way out and didn't disconnect the pump at all, I just repaired the impeller with the pump left in place.

Here are the illustrated steps.

You need to pull the refrigerator by removing the four screws around the front bezel, and set it aside.

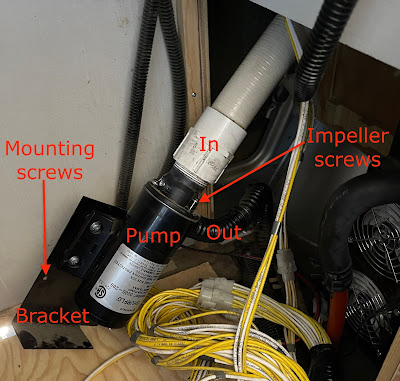

In the right rear, you see the macerator pump mounted to the van's frame with a bracket and four screws.

The pump is held in place with a bracket and 4 screws in the van's frame. This photo, with the pump removed, shows the locations of the bracket's screw holes.

In order to completely extract the pump from the van, you have to remove the four bracket screws, disconnect the INFLOW connection, disconnect the OUTFLOW connection, and cut the power leads. As shown in this photo, I took the easy way out and simply removed the four bracket mounting screws and loosened the pipe connection at the sink drain so that I could replace the impeller without having to disconnect anything else. In particular, the IN connection was affixed with some sort of cement that was too difficult to remove.

Removing the three 'impeller access screws' at the top of the pump reveals blades that must be removed with a 7/16" socket. With the nut and blades removed, the silver disc below can be lifted up.

Under the silver disc you find the impeller itself. Surrounding the edge of the pump at this seam is a soft gasket that must be replaced, along with the impeller. I used silicone grease on the gaskets.

There is also a gasket in the upper section ('lid') of the pump that must be replaced.

The impeller just pulls out of its chamber with a pair of pliers, sliding easily on the motor's spindle.

The replacement parts were approximately $35, and the part number is shown in the photo below.The cause of the macerator failure seems to be that the rubber impeller arms become fatigued, and they stop making a tight fit in the pump chamber. This picture shows 3 years of wear on the old, fatigued impeller. Note the bent impeller arms, in contrast with the new unit on the right.

If you decide to extract the pump from the van, you'll need to cut the pump's power wires. Since this is a maintenance item that must be performed every few years, it may make sense to install easy connections, like bullet connectors, for the next time. Ralph Hill informs me that the pump's wires are 14 gauge, and the WGO wires are 10 gauge.